Digital Robot Automation

ONE OF THE BIGGEST CANADIAN CAR PARTS MANUFACTURER

Our client is a Canadian company and one of the world’s largest producers of car parts and related services. We assisted them in building a new solution to optimize and automate the delivery of car parts from the warehouse to the assembly line, using robots.

The need

The customer has gigantic warehouses (totals to about 500 000 square feet) with hundreds of thousands of containers and workers who are responsible for moving them around. A lot of things were done manually (kept on papers, stickers on containers, using pencils), and the existing embedded application for scanning was not extensible and provided roughly 10% of the required functionality.

To meet the outcomes, we had to digitize everything, increase workers’ efficiency and gather big data for logistics optimization. There was a need to connect our mobile application to a bar-code scanner, which is used for container logistics, to enable workers to pick up tasks and monitor the progress digitally.

Shaping the future

Cognex mx-1000 bar code reader

The challenge

The warehouses were not covered by the network which meant the app to work in an asynchronous mode (offline/online). The app had to be integrated with external hardware – Bluetooth printers and container scanners to deliver the desired solution. Retraining existing staff for the new app meant no massive UX/UI changes as users are non-technical. Therefore, there was a need for a robust and straightforward redesign.

Last but not least, we had to integrate the app with a legacy backend system and deploy the app in a very secure environment with restricted internet access, VPN, AirWatch, and Azure Active Directory.

The app features

Offline sync

Changes are saved to local mobile storage and synced when the device is connected to the network.

Printing

The app can connect to Bluetooth printers and print labels with QR codes.

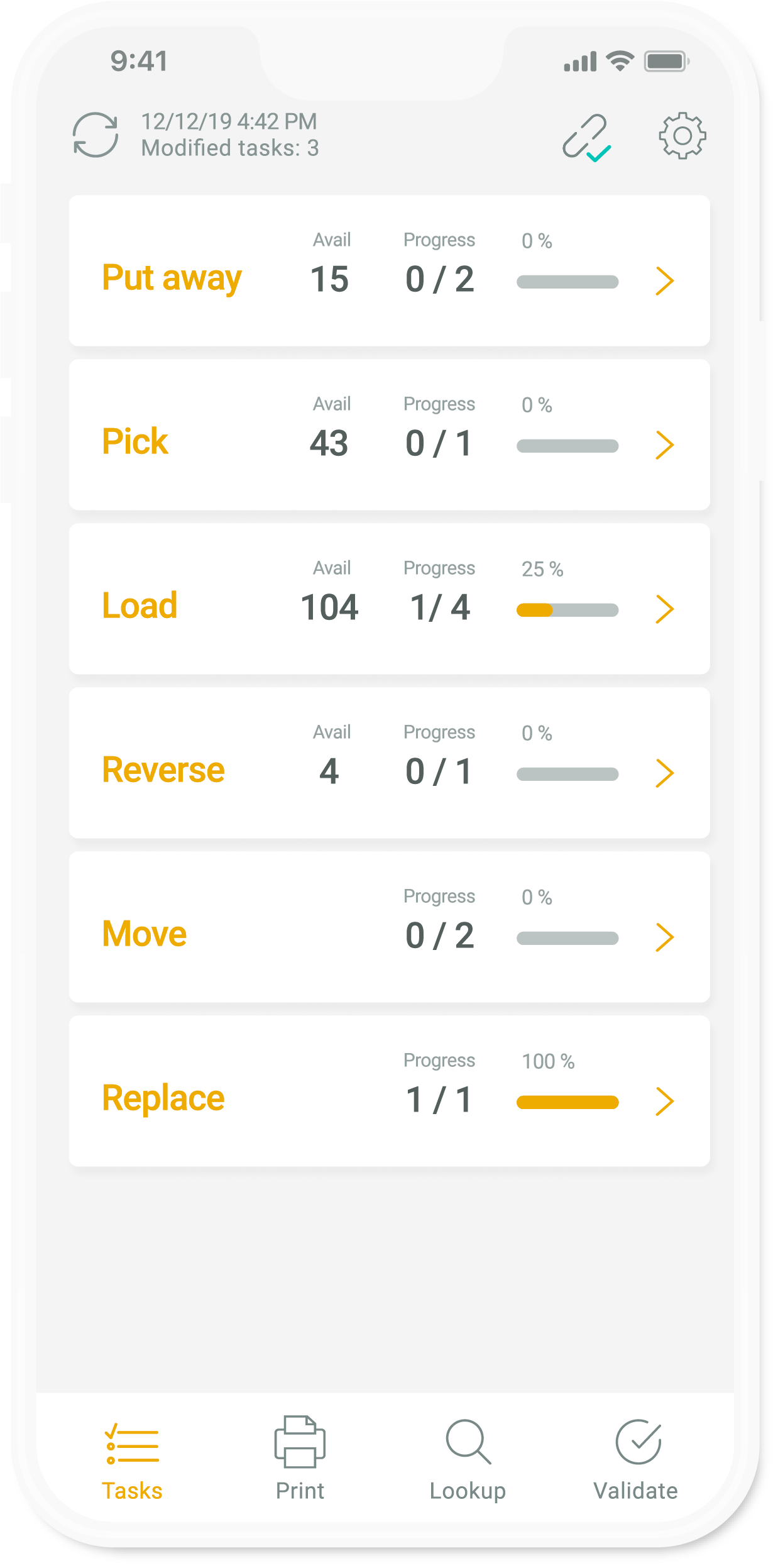

Task management

Users see what tasks they should work on and the status of tasks.

Barcode/QR code

The app can be connected to a Cognex scanner or device camera can be used to scan codes.

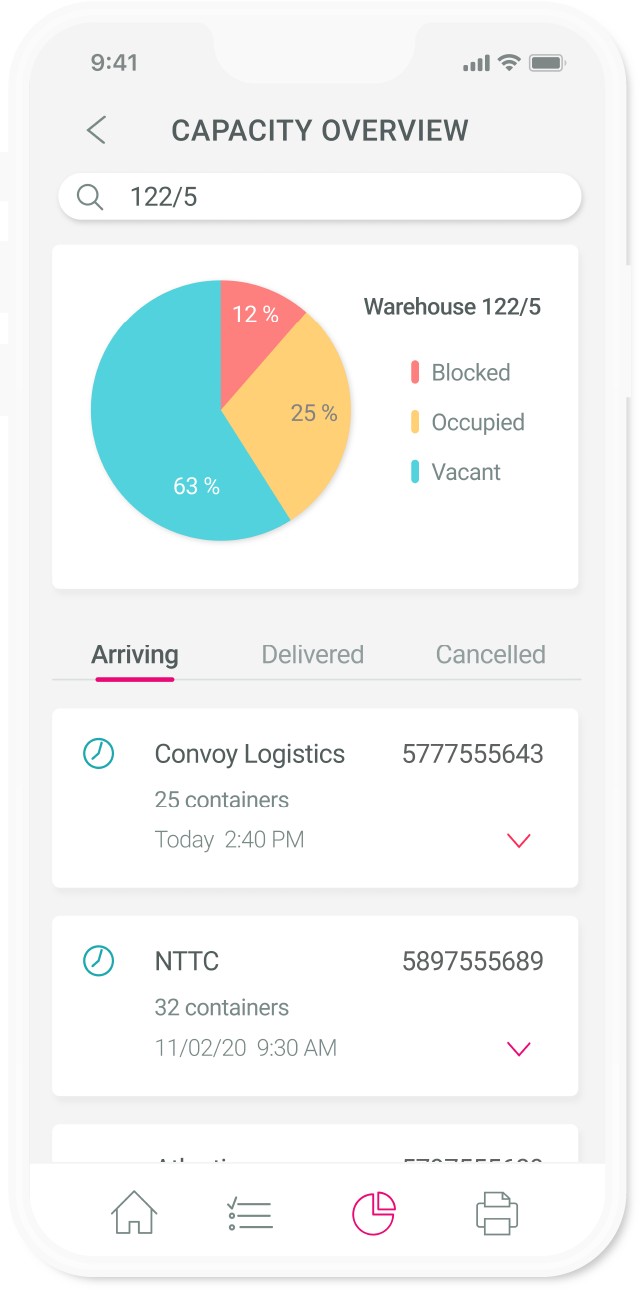

Smart lookup

The app provides info about the utilization of houses, bins or containers.

Developer tools

Unlocks a privileged mode and allows debugging of the app.

The solution

After understanding the client’s business needs, we focused on warehouse workers’ processes and their optimization. We set up the first meetings (remote calls) and were able to start after a month of analyses of the project. Building the app from scratch, we had meetings on a weekly basis with everyday internal short stand-up calls. An agile approach let us go fast and solve errors on the fly. To provide the desired multi-platform app solution, we used React Native framework and Typescript as a programming language.

The app enabled customers to connect a mobile phone with a bar-code scanner device with the possibility of mobile camera scanning as well. The app can be connected to a Bluetooth portable Zebra printer to reprint damaged bar codes. We implemented an easy and clean UI design as required for non-technical users. Besides, there is a developer tools interface in the app that can be turned on by privileged users. The app drastically improves the debugging experience for technical users and decreases the support cost for the whole company. The entire solution was integrated with the ASP.NET server which is connected to Oracle DB and SAP.